PRODUCTION

1. ROLLER-BEARING MACHINING PROCESS

2. BALL-BEARING MACHINING PROCESS

PRODUCTION:

PROCESS 1: RAW MATERIAL

THE COMPANY STRICTLY CONTROLS QUALITY IN THE INCOMING MATERIAL PROCESS, STARTING FROM THE SOURCE AND SELECTING HIGH-QUALITY MATERIALS.

PROCESS 2: FORGINGS

IN THIS STEP, THE BLANK IS FORGED. THROUGH FORGING, THE LOOSENESS AND HOLES IN THE METAL CAN BEELIMINATED, SO THAT THE MECHANICAL PROPERTIES OF THE FORGING CAN BE IMPROVED.

PROCESS 3: TURNING PROCESSING

TURNING TOOLS ARE USED TO TURN ROTATING WORKPIECES. THE COMPANY HAS A TURNING MACHINE WITH A DAILY PROCESSING CAPACITY OF * TONS, FULLY ENSURING THE FOLLOW-UP PRODUCTION OF BEARINGS.

PROCESS 4: HEAT TREATMENT

HEAT TREATMENT IS ONE OF THE IMPORTANT PROCESSES IN THE BEARING PRODUCTION PROCESS. THROUGH HEAT TREATMENT, THE PERFORMANCE OF THE BEARING CAN BE IMPROVED. THE HEAT TREATMENT PROCESS GENERALLY INCLUDES THREE PROCESSES: HEATING, INSULATION, AND COOLING. OUR COMPANY HAS A SUPPORTING HEAT TREATMENT ASSEMBLY LINE WITH UNINTERRUPTED CONNECTION AND HIGH PRODUCTION EFFICIENCY.

PROCESS 5: ROLLING ELEMENT PRODUCTION

ROLLING ELEMENTS ARE THE CORE COMPONENTS OF BEARINGS. THE PRODUCTION OF ROLLING ELEMENTS REQUIRES GRINDING AND SUPER-PRECISION. THE COMPANY HAS DOMESTICALLY ADVANCED ROLLING ELEMENT PRODUCTION EQUIPMENT AND IMPLEMENTS PRECISE AND HIGH-QUALITY REQUIREMENTS. IT CAN PRODUCE BALLS, CYLINDRICAL ROLLERS, AND CONES OF VARIOUS SIZES. ROLLERS, NEEDLE ROLLERS, ETC. THE PRODUCTION RANGE IS COMPLETE, WHICH CAN GUARANTEE THE PRODUCTION OF BEARINGS TO THE GREATEST EXTENT.

PROCESS 6: PROCESSING OF INNER AND OUTER RINGS

THE BEARING RING INCLUDES THE PROCESSING OF THE INNER RING AND THE OUTER RING. IT UNDERGOES GRINDING AND ULTRA-CLEANING OF THE WORKING SURFACE. IT CAN ALSO BE PRECISION PRODUCED WITH STOP RINGS, RETAINING RINGS, ETC.

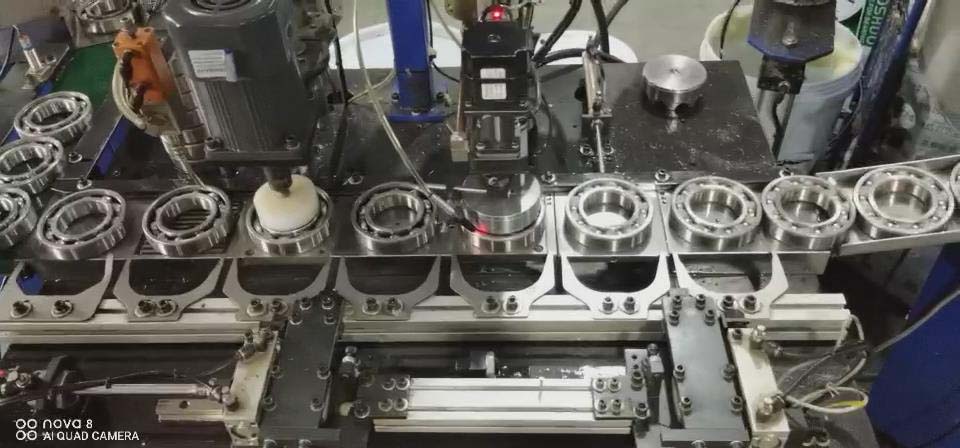

PROCESS 7: DUST-FREE ASSEMBLY

THE COMPANY'S ASSEMBLY WORKSHOP IMPLEMENTS DUST-FREE MANAGEMENT. THERE ARE SMOOTH PRODUCTION LINES FOR MANUAL ASSEMBLY AND ASSEMBLY OF INSTRUMENTS,AND THE ASSEMBLY IS MORE RIGOROUS. THE COMPANY'S ASSEMBLY WORKSHOP HAS STRICT MANAGEMENT, STERILE AND DUST-FREE MANAGEMENT, AND HAS A GROUP OF SKILLED TECHNICAL ASSEMBLY PERSONNEL.

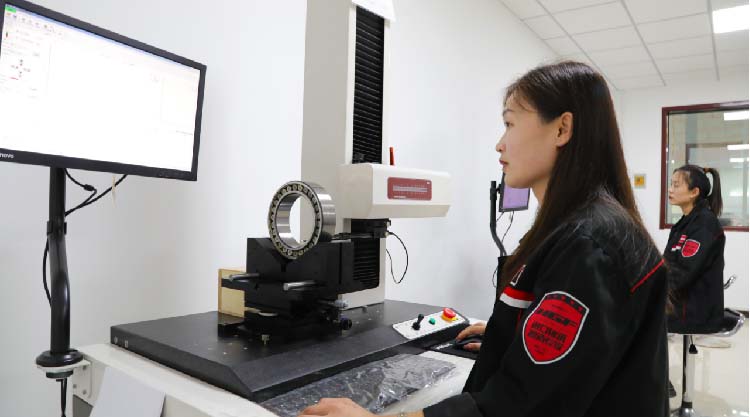

PROCESS 8: QUALITY INSPECTION CENTER

THE COMPANY HAS AN INDEPENDENT QUALITY INSPECTION LABORATORY. IN ORDER TO ENSURE THE QUALITY STABILITY OF ITS PRODUCTS, THE COMPANY HAS INVESTED IN TESTING EQUIPMENT SUCH AS SPECTROMETERS, LENGTH MEASURING INSTRUMENTS, PROFILOMETERS, ROUGHNESS METERS, FLAW DETECTORS, MICROSCOPES, GERMAN ZEISS CMMS, AND BRITISH TAYLOR ROUNDNESS METERS. . THE COMPANY HAS THE MOST ADVANCED TESTING EQUIPMENT FOR PRECISION BEARINGS AND NOISE TESTING. THE STAFF OF THE QUALITY INSPECTION DEPARTMENT HAVE ALSO UNDERGONE STRICT TRAINING AND ARE HIGHLY SKILLED AND CAN ACCURATELY DETECT VARIOUS INDICATOR DATA.

PROCESS 9: CONSTANT TEMPERATURE THREE-DIMENSIONAL

THE COMPANY HAS A FLAT CONSTANT-TEMPERATURE THREE-DIMENSIONAL WAREHOUSING SPACE. IT HAS COMPLETE INVENTORIES OF ALL CATEGORIES OF BEARINGS AND A LARGE STORAGE CAPACITY. THE WAREHOUSE DISPLAY RACKS ARE CLASSIFIED ACCORDING TO SERIAL NUMBERS AND THE WAREHOUSE TEMPERATURE IS CONSTANT. IT IMPLEMENTS STRICT WAREHOUSING MANAGEMENT PRINCIPLES AND AN EFFICIENT STORAGE VOLUME FEEDBACK SYSTEM, WHICH CAN SHORTEN THE DELIVERY CYCLE AND ENSURE THE FASTEST EFFICIENCY TO MEET CUSTOMER NEEDS.

QUALITY INSPECTION EQUIPMENT:

1.ZEISS THREE-DIMENSIONAL COORDINATE MEASURING MACHINE

2.ROUGHNESS PROFILER X-3 160

3.WALL THICKNESS MEASURING MACHINE H904

4.ELECTRONIC HEIGHT GAUGE

5.HEIGHT MEASURING MACHINE6.ROLLER MEASURING MACHINE D051

7.INNER DIAMETER MEASURING MACHINE D713

8.INNER DIAMETER VERTICAL DIFFERENCE MEASURING INSTRUMENT C923

9.OUTSIDE DIAMETER MEASURING INSTRUMENT D914

10.UNIVERSAL MEASURING INSTRUMENT D904

11.CLEARANCE MEASURING INSTRUMENT X293A

12.VIBRATION TESTING MACHINE